- HOME

- PRODUCTS

- Customized Products

- Customized Products

- Customized Products

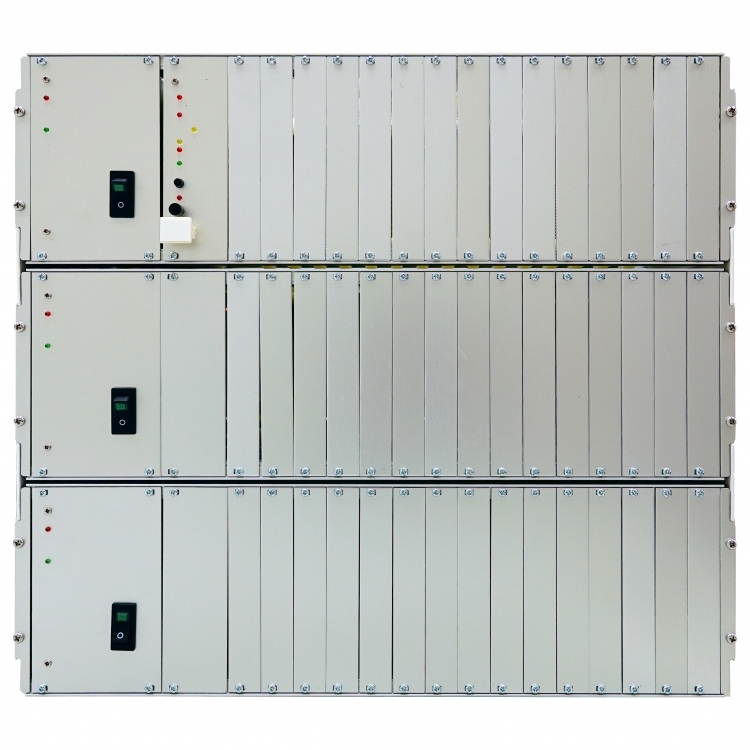

- FA-LRA-3TBMPNP

FA-LRA-3TBMPNP

- Flexible combination of functional modular design

- High-efficiency material transportation

- Precise pressure differential monitoring

- Energy-saving operational design

- Flexible parameter adjustments

- Reliable operational stability

- Easy maintenance operations

- Fully automated control functions

1. Product Introduction

FA-LRA-3TBMPNP is a central control device specifically designed for industrial material handling systems. Its modular structure and high-efficiency performance meet the material transport needs of systems of various scales.

With precise control and flexible configuration, the FA-LRA-3TBMPNP is an ideal choice for automation and efficiency improvement on production lines.

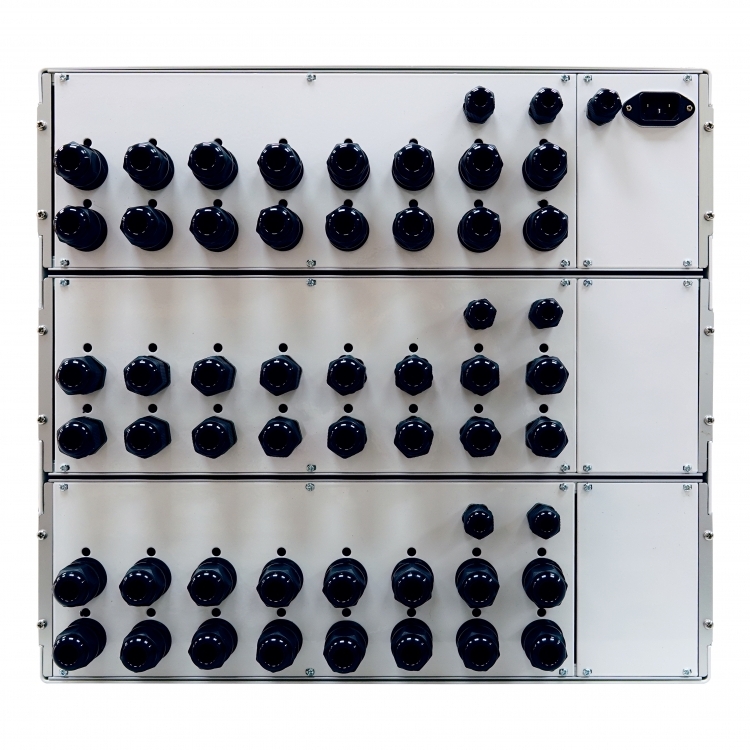

2. Applicable Scope

- METRO HLX Hopper Loaders: The best choice for single-point or multi-point material transport, suitable for small to medium-sized systems.

- METRO MLX Hopper Loaders: Suitable for medium to large-scale production transport, ensuring stability and efficient operation.

- Blower Systems (X Series): Responsible for air dynamic management in the system, providing stable negative or positive pressure transport support.

3. Core Function Modules

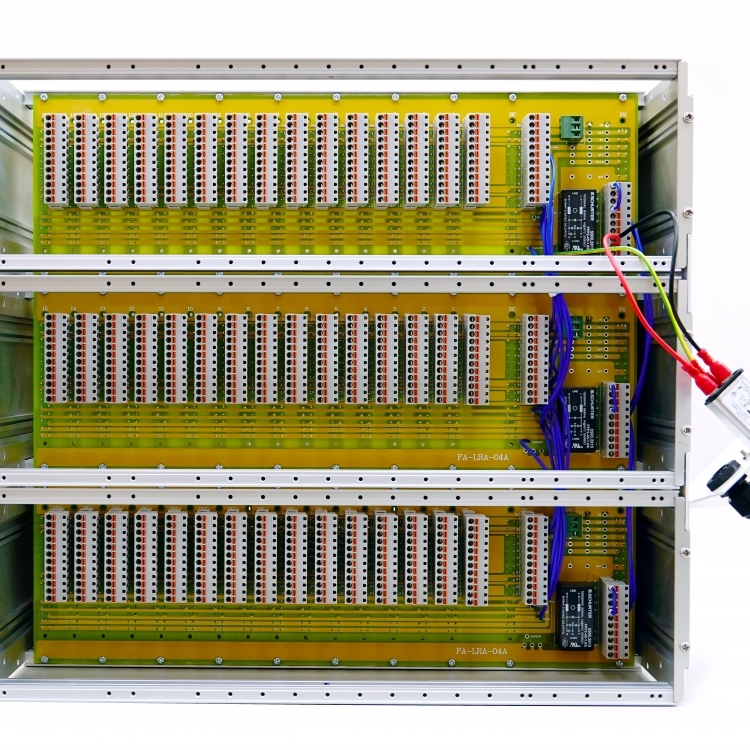

-

Main Control Card

The main control card is the core of the system, responsible for central management and coordination, monitoring, alarm, and implementing core system functions. -

Blower Control Card (FA-LRA-04B)

- Functions:

- Delay start/stop settings to optimize system performance and reduce energy consumption.

- Monitors system pressure differential and alerts for filter cleaning when necessary.

- Controls blower operation and integrates central alarm function.

- Application: Ideal for managing airflow in the system, ensuring stable and efficient transport.

- Functions:

-

Sub Control Cards

Sub control cards are responsible for the detailed control of specific units, including material bins and cleaning systems. -

Unit Control Card (FA-LRA-04C)

- Functions:

- Equipped with signal lights to quickly reflect material shortages and ensure timely replenishment.

- Built-in vacuum counters for monitoring material demand and transport status.

- Controls material transport for a single material bin.

- Application: Suitable for small systems with single-material bin transport needs.

- Functions:

-

Support Modules

Support modules assist main and sub-control cards in operation, providing stable power and status monitoring. -

Power Supply Module (FA-LRA-04D)

- Functions:

- Equipped with indicator lights to show operational and abnormal status.

- Provides stable 24V DC power for main and sub-control cards.

- Application: Supports the stable operation of the entire system, providing power to all control modules.

- Functions:

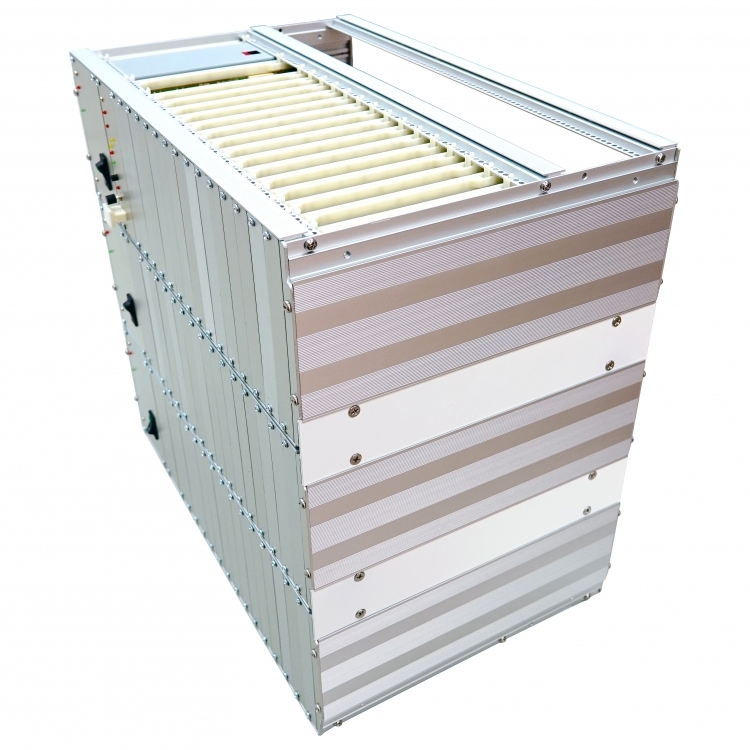

4. Product Technical Features

-

DIP Switch and Potentiometer Settings

- Transport Time: Adjustable short transport mode (2-31 seconds) and long transport mode (6-120 seconds).

- Cleaning Cycle: Flexible settings from 20 minutes to 10 hours, adaptable to different material characteristics.

- Alarm Delay: Range from 4 seconds to 25 minutes to avoid unnecessary alarm disturbances.

-

Operating Environment and Protection Rating

- Protection Rating: IP54 (optional), suitable for various industrial environments.

- Device Stability: Long-term operation with minimal maintenance requirements.

5. Product Advantages

-

Modular Design

- All control modules can be flexibly combined and replaced, meeting different factory expansion needs and facilitating upgrades and maintenance.

-

High-Efficiency Transport Capability

- Precise pressure differential monitoring and flexible delay settings ensure stable and efficient material transport system operation.

-

Multi-Function Control Options

- Supports single-material and dual-material bin transport modes, and can mix and transport multiple materials, adapting to dynamic production scenarios.

-

Energy-Saving Design

- The blower delay start/stop feature reduces energy waste and extends equipment lifespan.

-

Easy Maintenance

- Easy-to-operate cleaning and maintenance procedures, filter status indicators, and maintenance reminders reduce downtime.

-

Wide Application Range

- Suitable for industries such as plastics processing, chemicals, and food packaging, meeting various industrial environment needs.

-

Stable and Reliable Design

- Protection ratings and high-quality modular components ensure stable operation even in harsh environments.

6. Common Problem Solutions

- System not feeding material: Check material levels and vacuum pipelines for blockages or obstructions.

- Blower failure to start: Check control circuits and filters, clean or replace filters if necessary.

- LED indicator abnormal: Verify power supply module connections, replace fuses or service the power supply module if needed.

7. Maintenance Recommendations

- Regular Cleaning: Clean filters and air ducts to ensure smooth transport.

- Replace Consumables: Regularly replace fuses and filter components based on usage frequency and system status.

- Preventive Maintenance: Perform regular checks to prevent failures that may affect production efficiency.

FA-LRA-3TBMPNP is a central control device that combines high performance, flexible configuration, and reliable operation, designed for modern industrial material handling needs.

| Specification | Data |

|---|---|

| PLC BRAND | SERIES | ITEM NO. |

|---|